Inspect by Machinery Partner revolutionizes heavy equipment inspections by transforming traditional paper-based processes into a streamlined digital workflow. This mobile-first solution addresses critical inefficiencies in the industrial equipment sector while ensuring reliability in challenging environments.

Background

In the heavy equipment industry, pre and post-delivery inspections are crucial but often hindered by outdated paper-based methods. These traditional approaches lead to numerous challenges including lost documentation, damage from environmental factors, and inefficient data management. Machinery Partner identified an opportunity to modernize this critical process through a purpose-built digital solution.

Challenges

- User adoption: creating a digital solution that proves more efficient than pen and paper while being intuitive enough for technology-resistant OEMs.

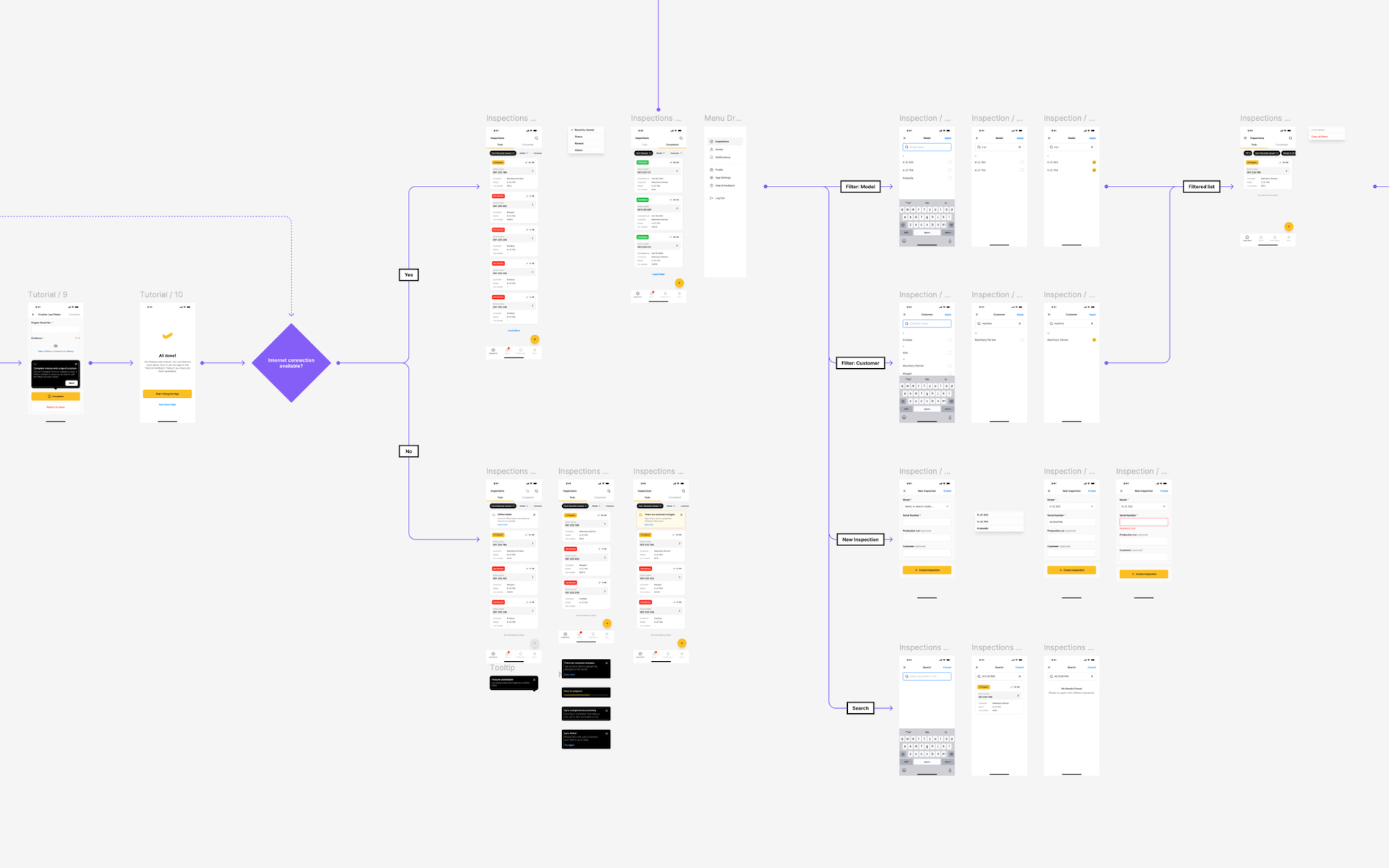

- Offline functionality: developing a robust system that functions reliably in rural environments with limited or no cellular coverage.

- Complex workflows: accommodating varied inspection requirements across different equipment types and manufacturers while maintaining simplicity.

- Stakeholder alignment: balancing the needs of multiple user groups including service technicians, managers, and administrators.

Solutions

Comprehensive research

- Conducted on-site field research with major manufacturers including Komplet (Italy), Omega Crusher and Barford (Northern Ireland)

- Gathered insights from service technicians, managers, and shift supervisors

- Performed competitive analysis and explored emerging technologies like OCR and AI

User-centered design process

- Created iterative designs with continuous stakeholder feedback

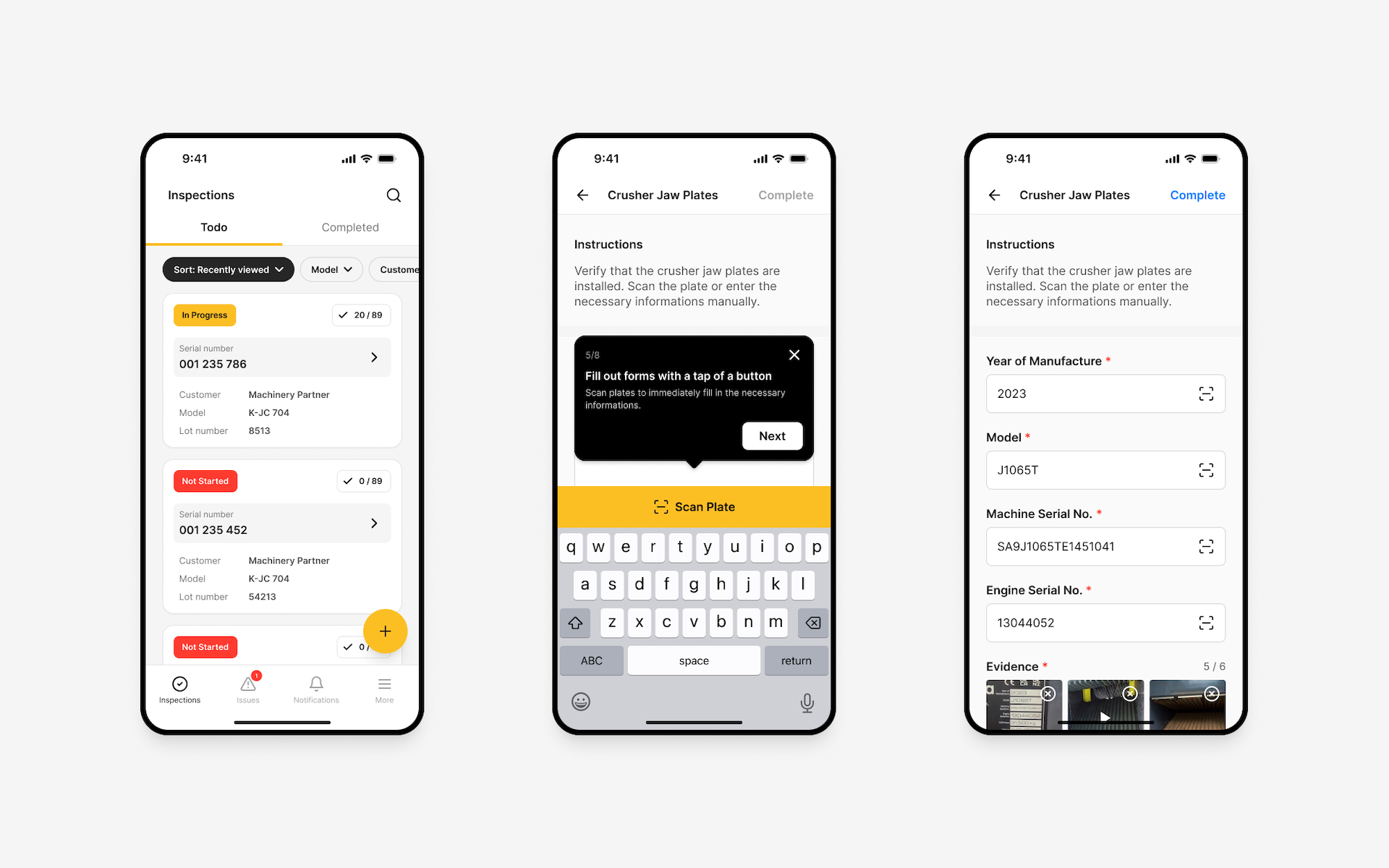

- Developed intuitive user flows for both field operations and administrative tasks

- Established clear information architecture supporting complex inspection workflows

- Designed a component system optimized for mobile use in industrial environments

Technical innovation

- Implemented offline-first architecture ensuring functionality without cellular coverage

- Integrated AI and OCR technology for rapid label and part number scanning

- Developed background synchronization system for seamless data management

- Collaborated with development partner Zazmic for implementation

Enterprise features

- Custom inspection template creation capability

- Real-time issue reporting with automated notifications

- Digital signature capture and PDF report generation

- Comprehensive admin interface for inspection management

Impact

The Inspect app delivers significant improvements to the equipment inspection process:

- Dramatically reduced inspection time through digital automation

- Eliminated paper-based documentation risks

- Enabled real-time communication between field technicians and managers

- Provided searchable digital records of all inspections

- Standardized inspection processes across different equipment types

Conclusion

By digitizing and streamlining the equipment inspection process, Inspect demonstrates Machinery Partner’s commitment to modernizing industrial workflows. The solution successfully balances technical innovation with practical usability, creating a tool that enhances efficiency while being accessible to all users regardless of their technical proficiency.